As one of the riskiest jobs in the world, mining has been under heavy development over the years. This has led to preventing death and reducing mortality to below 20 cases per year in America. Besides death prevention, the development has led to mechanization that surely increases productivity.

Creating automatization, and improving the machinery is just a couple of ways to increase productivity. In this article, we’ll provide a couple of tips to implement in your underground mine to improve productivity and make the mine safer for everyone. Keep reading and learn more.

Invest in wireless communicating devices

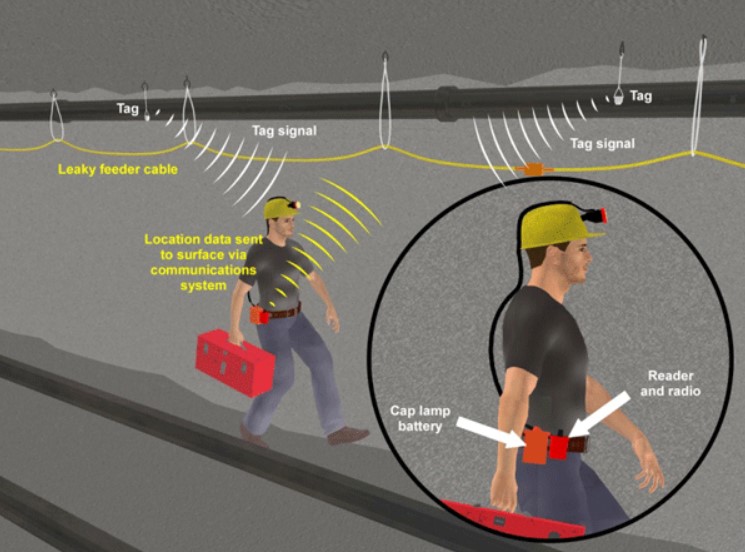

In the underground, there is no regular service since the miners are usually 40 meters or more beneath the ground. For that reason, there has to be another way to ensure proper communication. Previously, there were wired devices or pagers that workers could not always use or access.

By swapping that system with a wireless communicating device and giving one to every employee many benefits follow. They will be able to communicate which will contribute to a more productive environment. In addition, the wireless devices are usually equipped with a GPS module which helps in situations where workers are trapped beneath the ground.

With the implementation of a simple communication system, you are surely increasing safety, and making mining more productive. When there is a problem, they can simply contact each other and assess the situation properly.

Create automation processes

By creating automation processes, the machines can work on their own and there is no need for a person to be around. This surely decreases the chases of a disaster, and a person risking their life without a need.

In addition, by removing the chance of a human mistake, mining becomes more productive. Keep in mind that the machinery can work while the employees are not around. This contributes to non-stop mining which is the most productive option.

Collecting and analyzing data

In every industry, the data that is collected through the working process is essential for future improvements and adjustments. For example, we can take airflow as a marker of safety. Some devices are measuring the amount of oxygen in certain work areas, and managers can see that.

Whenever there is an insufficient amount of oxygen, they can boost the flow through the ventilation and improve the working conditions. All information is saved so it can be accessed again for further analysis.

Investing in new machinery

You cannot improve the mining productivity if you are having outdated machinery. There will be a constant obstruction in the workflow, which will frustrate both the workers and directors. In addition, old trucks, diggers, etc. are prone to breaking and damage. When there is a need for constant repairs, they become unreliable and unsafe for your employees.

For that reason, investing in new dump or mining trucks is essential in every mining business. However, you have to be careful about the brands you purchase from. Be sure to get your machines from a reliable source like fuchenglhd.com so you can get warranties and high-quality trucks.

Before you consider buying new machines, do research and find out what you need. By purchasing the best option for your situation, you are increasing both the safety and productivity inside your underground mine.

Be sure to maintain the equipment

No matter how high-quality machinery you purchase, by failing the maintenance process, they will not last long. For that reason, you should come up with a schedule to be sure everything has been checked and fixed on time.

This can be done during the time off work or by coming up with a schedule to rotate the machines that have to be maintained. That way, you will not obstruct the workflow which is surely beneficial. By having your machinery regularly maintained, you are contributing to the increase in mining productivity.

Use of drones

The ability to receive information without risking someone’s life is something we have achieved with the technology’s progress. For that reason, using drones in mines is a way to inspect and analyze the slopes without the need for the geologist and engineers to get inside.

In addition, the drones give you the ability to catch a glance of the whole mine from perspectives that were previously not available. When there is a simple device that dramatically helps the process of making the mine safer for everyone, using it should be a must.

Self-aid products

The ability to keep the miners safe is a priority you must focus on. For that reason, providing a self-aid device for every worker should be mandatory. There are self-contained systems with oxygen for situations when there is a gas leak, or the miner gets trapped underneath. They can simply pull out the device and have enough oxygen until getting rescued.

By increasing the safety inside the mine, you are increasing the productivity second-handed. For that reason, focusing on safety is the number one thing that has to be done.

Use of synthetic ropes

Ropes are an essential piece of equipment to provide safety for every miner. With different types of ropes, it can be hard to find the right one. At the moment, most mines have wire ropes. Although they are sturdy and durable enough when they break there is a recoil that can damage surroundings and people.

For that reason, switching to synthetic ropes should be a better decision. They are also durable and sturdy, but when they brake, they are safer for the miners and the surrounding area. By providing safer equipment, there will be no situations of unneeded injury and productivity is being increased.

Proper placement of the equipment

Since most machines are working on rails, there is a high chance of collision. Collisions are a big factor in injuries and bad consequences inside mines. For that reason, ensuring the proper placement of the machines is highly important.

Many mines have implemented sensors for proximity to prevent such situations. When there is a machine nearby, the device gives a signal to slow down or completely stop. On the surface of the mines, collisions can be prevented by the implementation of the GPS.

Conclusion

By providing safe working conditions productivity only rises. The workers will feel safer which will make them work harder. In addition, the new machinery that you have provided will surely make some tasks easier.

Be sure to constantly track the data and observe the mine, that way, you can quickly adjust and make the workplace more favorable for the workers. This will surely contribute to a more productive underground mining, more satisfaction, and profits.