For every pharma industry, tablet pressing machines are helpful. These are also known as tablet compression machines and pharmaceutical tablet press machines.

This tablet pressing machine makes different variations of tablets in uniform shapes from materials like powder and granules. During tablet formulation, the powder fills the space created by the punch and the machine’s die. Then the points are pressed to form a tablet.

Categories Of Tablet Press Machines

There are two categories of tablet press machines for the production of tablets. They are

Single Station Press Machine

A single-station tablet press machine compresses powder into tablet form, having a variety of uniformity in size, shape, and weight.

This machine produces fewer quantities of tablets for different ranges of applications, right from cosmetics industries and pharmaceuticals to cleaning product industries.

It is also suited for research and development departments that require the production of small batches of new materials involving low-cost methods. This machine could also be utilised for producing industrial catalysts for petrochemical industries.

Multi-Station Press Machine

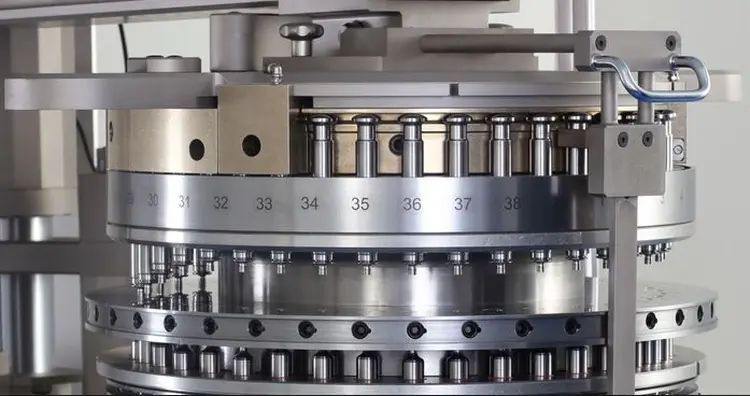

The multi-station press has several stations that rotate to compress powder or granules into the tablet form consisting of exact size, shape, and weight. It produces large quantities of tablets in less time. This press is also known as a rotary tablet press.

In this type of tablet press, the force to fill material gets applied on the upper and lower punches, which leaves the powder granules packed in the middle, also known as wind box type of compression. The tablet press’s capacity depends on the current’s current speed and the number of stations.

In short, more production of tablets is achievable along with the minimum amount of labour, which saves money. This press gives an output between 9000 – 234000 tablets per hour, saving production time and meeting the demand for tablet dosage. The moving feeder automatically manages the powder-filling cavity.

The machine controls the tablets’ weight and hardness and also decreases wastage.

Tablet Press Machine Advantages

The single-press tablet machine is straightforward to operate with a high usage ratio. It is ideal for producing tablets in small batches with less quantity.

Multi-station tablet machines could produce a larger quantity of tablets with less labour cost. It helps in decreasing the wastage of non-specific pills.

Both types of tablet press machines do not require much maintenance and are affordable. It helps produce dust-free tablets, which are easy to clean afterwards.

Tablet Press Machine Applications

These machines are utilised in pharmaceutical industries, mainly for the production of tablets. Depending upon the quantity and other relevant details required, these get used in research departments that develop tablets for experimenting.

They are utilised in different industries like ceramic, herbal, and other industries. These machines help manufacture chewable tablets containing mannitol, binders, and other ingredients.

It produces effervescent tablets containing substances like tartaric acid, citric acid, sodium bicarbonate, and a wide variety of compressed tablet formulas.

Conclusions

The tablet press machines have good usage of producing a wide variety of tablets. These machines don’t require much maintenance and can easily take care of a high volume of tablets most efficiently and accurately, thus helping several industries as it handles various ingredients used.