Prototyping is very important in 2024, as we constantly have new products coming out on the market that need to be tested first before released officially. Thanks to technology, we have a lot of ways of creating those prototypes, one of the two most famous ones being 3D Printing and CNC Machining.

There’s no denying that these two methods, or should we say technologies, revolutionized the way this entire industry functions. They are equally important, but as everything else in life, each one has its pros and cons. In today’s article we’ll do some comparing, because this is something frequently asked by the community. Everybody wants to know whether 3D Printing or CNC Machining is a better choice in 2024, so we decided to do the homework for you.

Although it’s a subject that requires a lot of specifying and technical terms, we’ll try to keep this comparison as simple as possible. Our goal is for everyone to be able to understand it regardless of their knowledge in both areas. It’s a very interesting subject and we’re excited to talk about it, so let’s end this introduction right here and jump straight into the content.

The difference between subtractive and additive

Whenever you hear someone talking about the differences between 3D Printing and CNC Machining, the first thing they mention is subtractive vs additive manufacturing. Although these terms sound quite complicated at first, they are actually very, very easy to understand once someone breaks it down for you. Today, we’re the ones simplifying things for your ease, so let’s take a look.

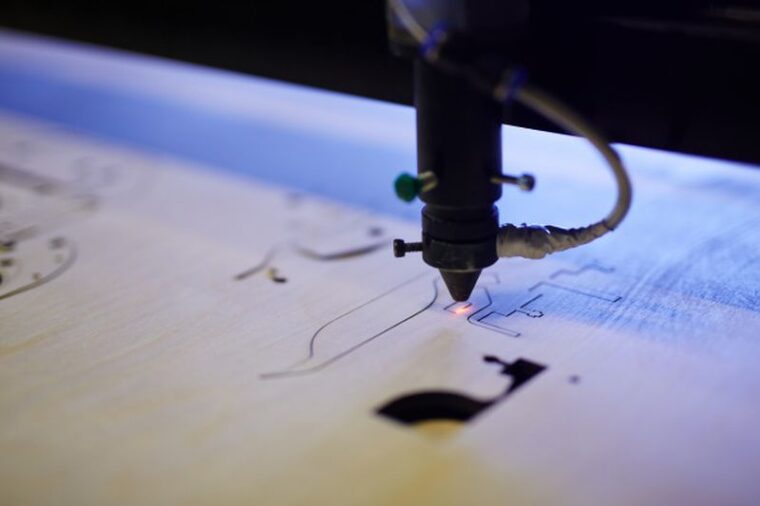

Basically, subtractive manufacturing is what CNC Machining uses. With a CNC machine, you take an entire block of any material, and then you cut it down precisely to get the form you need. It’s called subtractive because you are basically subtracting parts of the block in order to get the final result. But, what you end up with is a lot of waste. The waste is unused material in the form of cuts in very irregular and inconsistent shapes.

Then there’s additive. This is basically the method that 3D printing uses, which is slowly building up the required shape with the chosen material. This process allows for much less waste because it’s a lot more precise and delicate. But, it’s a bit more complicated to do and it usually takes more time. Of course, we’re not the ones doing it, the machine does it, but still, the time it takes to finish is in most cases longer. Of course, this will solely depend on the complexity of the model. In additive manufacturing, the product is being created layer after layer.

Please note that in some cases, 3D printing, or additive manufacturing can be faster, despite what we said above, which is spoken in general. Once again, it will depend a lot on the complexity of the model. For example, if you want to create a simple cube, subtractive can be faster. For more information on additive manufacturing, you can always check artmachining.com.

The simplicity war – Which one is easier?

In all honesty, we cannot neglect the importance of CNC machining in the industry even the slightest bit. However, when it comes to simplicity, we also cannot say that 3D printing isn’t a lot easier to get into. Basically, we see it this way:

3D printing is a modern and easy-to-do method for those who want to do it as a hobby. Sure, it can be done professionally, but nowadays it’s a “trend” and people do it for fun.

CNC Machining on the other side is a lot more professional in some way, if that makes sense. It’s used in the industry, and as far as individual use goes, only those dedicated to serious manufacturing have a CNC machine in their home. You can usually find these machines at faculties and universities that specialize in something like this, whilst 3D printers are available to see and use even at elementary schools.

Should this have any impact over your decision on which one is better? Not at all, we’re just stating facts, since this is a fair comparison guide. So, the ease-of-access of 3D printing automatically means more articles, videos, tutorials and guides about it on the internet. So, as a conclusion, 3D printing is probably easier to learn.

Accuracy in complex models

According to all tests that were done on a professional level in the industry, 3D printing is superior to CNC machining when it comes to accuracy in complex models. This basically means that if you are trying to create something very complex, such as a part for a medical gadget required at a hospital, you’ll be better off with 3D printing.

The same thing goes for moving parts, and basically anything that’s delicate. The smaller the parts, the more complex they are, the higher attention to detail needed, you’re better off with 3D printing, period. That’s what the results of many observations say.

We’re not going to bother you with unimportant numbers because it’s simply not worth it. Open any detailed guide that compares these two in this particular field and you’ll see for yourself. In this particular field, 3D printing wins. But, if we compare tolerance for example, CNC absolutely demolishes 3D printing in every aspect.

The eco-friendliness factor

It’s 2024 and people are trying to be as eco-friendly as possible. Some do it for the reputation of their business, others do it because they truly care about saving our only planet. Both situations are good, we don’t judge. Jokes aside, 3D printing is better in this aspect because of a very simple reason.

Remember what we said about subtractive manufacturing? Yes, you take a block, and then you “cut” it down into the shape you require. So, what is left after the process finishes? A lot of mess. Unused material that cannot be saved for something else due to the awkward shapes it was cut in. But, with 3D modeling, you don’t have this problem. The mess is minimal and you waste fewer materials. So, 3D printing is eco-friendlier, if you like to put it that way.